In this interview with Recontour Senior Operations Manager, Shrenik Karbhari, we delve into his groundbreaking first trip to China to visit suppliers. This journey marks a pivotal moment in strengthening Recontour’s global supply chain and understanding the intricate dynamics of international business relationships. The interview offers insightful revelations about the strategic decisions behind the visit, the on-ground realities of dealing with Chinese suppliers, and how these interactions are shaping the future of Recontour. Join us as we explore how this trip is not just about business transactions, but about building lasting partnerships and expanding horizons.

Question. What suppliers challenges are unique for you as an ecommerce aggregator?

Answer. Recontour’s focus is on smaller brands which the brand owner is unlikely to have ever visited manufactures. Making matters worse that weak relationship then needs to transfer us as the new owner, having strong suppliers’ relationships is incredibly valuable and the best way to do it is by developing personal relationships.

Q. This was Recontour first trip to visit your suppliers in China. How did you decide “now is the time” to make this happen?

A. Early in 2023, Kevin and Miguel had suggested that I visit the suppliers in China. We had discussed this on and off through Q1 and Q2 2023. During June and July 2023, I happened to be in India. In early June, we again started discussing the visit and it seemed like a good time to plan out the visit towards the end of July; because: A) This was an opportunity to live one of our Recontour’s core values, which is to be “Resourceful, do more with less”. I was already in India and doing a stop over in China was both convenient and frugal. B) It was a slow time of the year for the suppliers and all of them were able to accommodate our request for the visits. C) Meeting in end of July / early August would help with making any immediate changes to products for Q4 orders.

Q. Thanks to the scale of Recontour, you have been able to visit China, an opportunity which can be harder for some brands sellers. Why is it a good chance to go to China and visit your suppliers?

A. That is true, Recontour’s scale has provided an incredible opportunity to visit China. Visiting China helps a brand seller understand the scale and size of the infrastructure that China has built to support its vast manufacturing hubs. Be it the rail connectivity between hubs in the interior to the ports or the air connectivity between smaller cities and the large hubs of Shenzhen or Shanghai, the infrastructure is built to aid in the fast movement of finished goods and raw material. If at all feasible, I recommend all brand owners (whether small or large) to plan and visit China to meet with their suppliers. It will change their perspective on the supplier and the supply chain.

Q. What were your goals and hopes for the visit?

A. Our main goals for the visit were to meet with the suppliers, put a face to the names of our contacts and build on the existing relationship.

We did have secondary goals:

- Improve payment terms.

- Learn about the strengths and weaknesses of each manufacturer.

- Understand the export and outbound logistics.

- Meet with potential new suppliers.

We were hoping to come out of the visit with a better understanding of the manufacturing and logistics processes and to have a stronger, more productive relationship with our suppliers.

Q. Did you do any research about the Chinese business culture before traveling there? What are your main recommendations on this issue?

A. Even though the initial planning started about 6 weeks prior, the visit was finally planned only about 3-4 days prior to the travel. I had very little time to research about the Chinese business culture.

But my main learning was that Chinese businesses do not believe in a transactional relationship and that they prefer a long-term relationship with their customers. This resonated well with one of Recontour’s values: “Think long-term”. Building long-term successful brands would require a long-term strong relationship with our suppliers.

And as one of the goals of my visit was to strengthen our relationship with the suppliers, my intention was to consciously to reinforce that message to the suppliers in all the interactions.

Q. How did you plan the visit? What was on your check list? How many days have you spent there? Did you have to travel long distances or all the suppliers were closer?

A. I had to meet with 8 suppliers, with no two of them located in the same city or area. I also had to obtain a Visa which would take 4-5 weeks. And lastly, none of the reservations could be made before I had a confirmation that I got the Visa.

Here’s the checklist that I had:

- Chinese Visa – Gathering invitation letters from suppliers and getting a Visa in time to travel to China on the way back to USA were the biggest challenges

- Work out and finalize the itinerary – I had informed the suppliers of my tentative plans, pending a Visa approval

- Make air and hotel reservations – All the reservations were made 1 day before my planned travel date, as I received the Visa approval 2 days prior

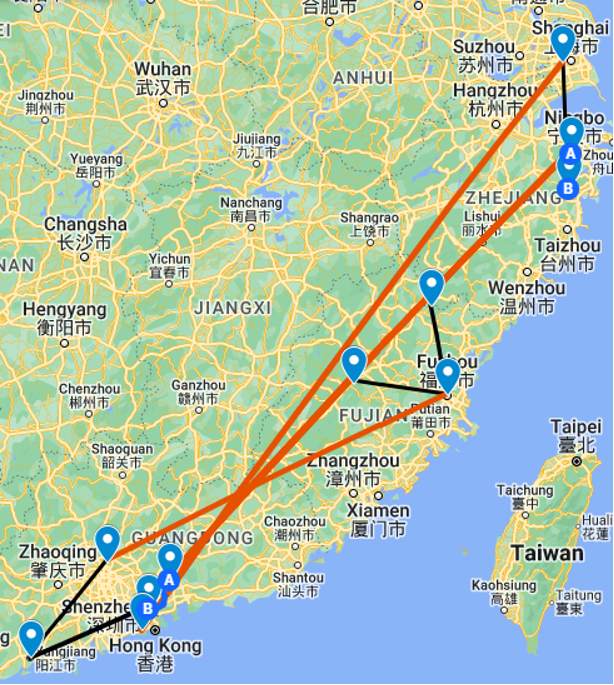

I spent 10 days in China, meeting with 7 suppliers. As none of them were close, I was taking a long distance train or a flight almost every day and ended up visiting 7 cities between Shanghai in the north and Shenzhen in the south. Here’s a map showing my trip across China.

Q. What advice would you have for a seller who is planning his first overseas supplier visit in terms of preparation and maximizing results?

A. Here there are my recommendations:

- Go with an open mind

- Sharing the visit agenda with your supplier is helpful

- Distances are large. Plan for more time in transit

- Get Alipay or Wechat Pay and add a physical credit card to use as payment method

- Get a local sim card / phone number

- Download a translator app or use a translating machine

- Download and use the China Railway app

- Subscribe to and download a VPN on all devices

- Try to avoid visiting in the crowded June-August timeframe as they are summer holidays

- Visit during April / October to club with the Canton Fair

- Research and plan for local transportation in advance

Q. Before visiting, Recontour only interacted with its suppliers online. How did meeting them face-to-face change the dynamic of those relationships?

A. The relationship with our suppliers has changed from a business-only relationship to more of a friendly / business relationship. There is a higher level of trust in each other, the suppliers understand and share our goals.

Operationally, the biggest difference is in communication. Previously, communication with supplier was done mostly through emails. That has now changed to a mix of emails and communication via WhatsApp. The instant messaging options helps to sort out minor issues related to production, packaging and shipping much quicker. We also have a better understanding of the rationale when a supplier notifies us of a delay in production or a change that needs to be made to the packaging, for example.

Q. What other key insights did you have by seeing the manufacturing processes, operations and logistics in person versus managing them remotely?

A. Scalability: After viewing the manufacturing facilities, we have a confirmation that the suppliers can support us in our growth plans. We can scale our brands / products and launch new products without any constraints on the manufacturing operations.

Supply side of manufacturing: we have a better understanding of the raw material procurement process, the parts of the product that are outsourced by the suppliers and the time it takes to procure / manufacture all the parts for final assembly.

Export process: Gathered a lot of new information about the logistics involved with exporting our products. We have better understanding of why some products / shipments are EXW vs. FOB, how the various FOB fees are impacted by the size of the shipment and the time needed to deliver a shipment from factory to the port or airport.

Q. Were there any positive surprises or “aha moments” when you saw the facilities up close?

A. The biggest aha moment was when I saw the manufacturing facilities in person. I did not expect our suppliers’ manufacturing facilities to be of the size that they are at. I went expecting much smaller operations and was surprised to find their scale. Each of the factories I visited was professionally managed.

Q. What issues were you able to identify by understanding the full context and story behind the manufacturing operations?

A. After observing the manufacturing process and learning about the operations, I now know the reasons behind —

- Certain products having a high MOQ for ordering

- Packaging and quality control issues

- Long lead time for manufacturing

Q. How will this on-the-ground experience influence your product development, quality control, and logistics going forward?

A. After having a first-hand experience and observing the manufacturing processes, we are now equipped with much more knowledge and detailed information to improve logistics, introduce stricter quality control methods and consider launching new products. Specifically –

In logistics: we are exploring option to consolidate products from 2 or more suppliers and ship together on a single shipment for cost efficiency.

In quality control: we are replicating the inspection method of one of our factories to other factories where there is less stringent quality control.

Q. What inspiring moments or interactions stood out from your supplier visits? Any remarkable stories?

A. What I recall the most is that all the suppliers were very helpful and attentive to our needs. Even though Recontour is one of the smaller volume customers for most of the suppliers, they were eager to strengthen our relationship and extend support for our future growth plans.

Personally, as well, they were extremely helpful. All the suppliers made efforts to meet my dietary restrictions when we had lunch or dinner together and arranging local transportation for me.

There was one situation that is worth mentioning –

After meeting with one of my suppliers in Nanping, I was travelling back to Fuzhou by train. A typhoon had just made landfall the previous night. So the trains were running late, most of the city of Fuzhou was closed and transportation shut down. Our supplier in Fuzhou was in constant communication with me. She had one of her colleagues wait at the train station for me. Once I arrived in Fuzhou, her colleague located a private taxi outside the train station for me, negotiated the fare and ensured that I was in the taxi going back to the hotel, before heading to back to her home. This demonstrated a lot of care and went a long way to build a trusting relationship.

Q. Overall, how did this trip change or enrich your perspective on the possibilities of Recontour? Any new range of products coming soon?

A. The most important outcome of this trip was that we now have a much better understanding of our suppliers’ operations and how business is done in China. We have a much better rapport with our suppliers now. Instead of simply being supplier, they have now become partners in achieving our growth targets. We are better suited now to make decisions about our Supply Chain.

We are also considering launching new products for some of brands. Some of our suppliers have off-the-shelf products that are complementary to our existing portfolio. It would be relatively less complicated to launch such products for a test.

Lastly, we are also exploring the possibility of working with a new supplier for one of our brands, whom I met with during this trip.